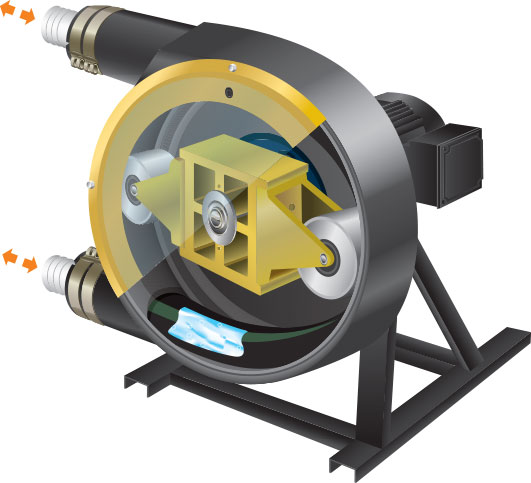

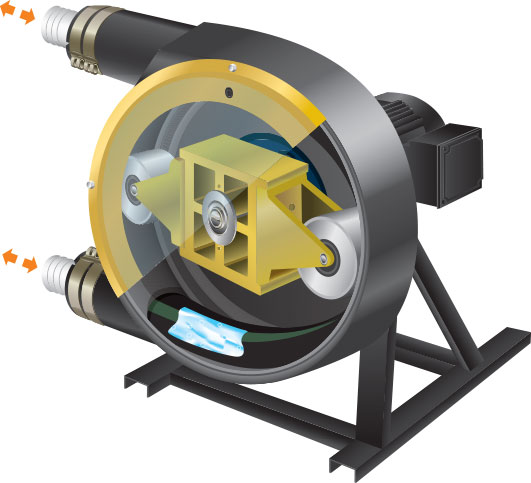

Vector pumps isolate the fluid being pumped into a single, durable hose so they can handle tough fluids.

Peristaltic Pumps from Vector Pump

Tel (612) 332-5681

Email: sales@wannereng.com

Wanner Engineering, Inc.

1204 Chestnut Avenue<br>Minneapolis, MN 55403 USA

Vector pumps isolate the fluid being pumped into a single, durable hose so they can handle tough fluids.

Up to 218 psig discharge pressure

Up to 211 gpm

Fluid is contained in the hose and only contacts the hose

Fiber-braided or extruded hoses can handle abrasive or corrosive fluids as well as food products or pharmaceutical materials

Transfers food and pharmaceutical solutions without crushing or foaming the fluids

Requires no priming chamber; suction lifts to 29-1/2 feet depending on model

Externally lubricated hose enables the pumps to run dry without stalling or damaging the hose or roller assembly; avoids pump failure and reducing pump life

out, or need replacement

Can pump abrasive fine particles and solids up to 3-1/2 inches (90 mm)

Reversible rotary movement provides for easy-to-clean system piping; flushing may be eliminated

Simple replacement of hoses saves time; clear plastic cover allows the pump to be checked easily during operation for any problems

A Vector pump can be used as a vacuum pump and for cleaning up spills; evacuates gases as well as fluids

A Vector pump is also a positive displacement pump for metering; output flow is directly proportional to pump speed

Vector pumps are ideal for several applications in production of industrial and commercial paints, coatings, inks, and dyes.